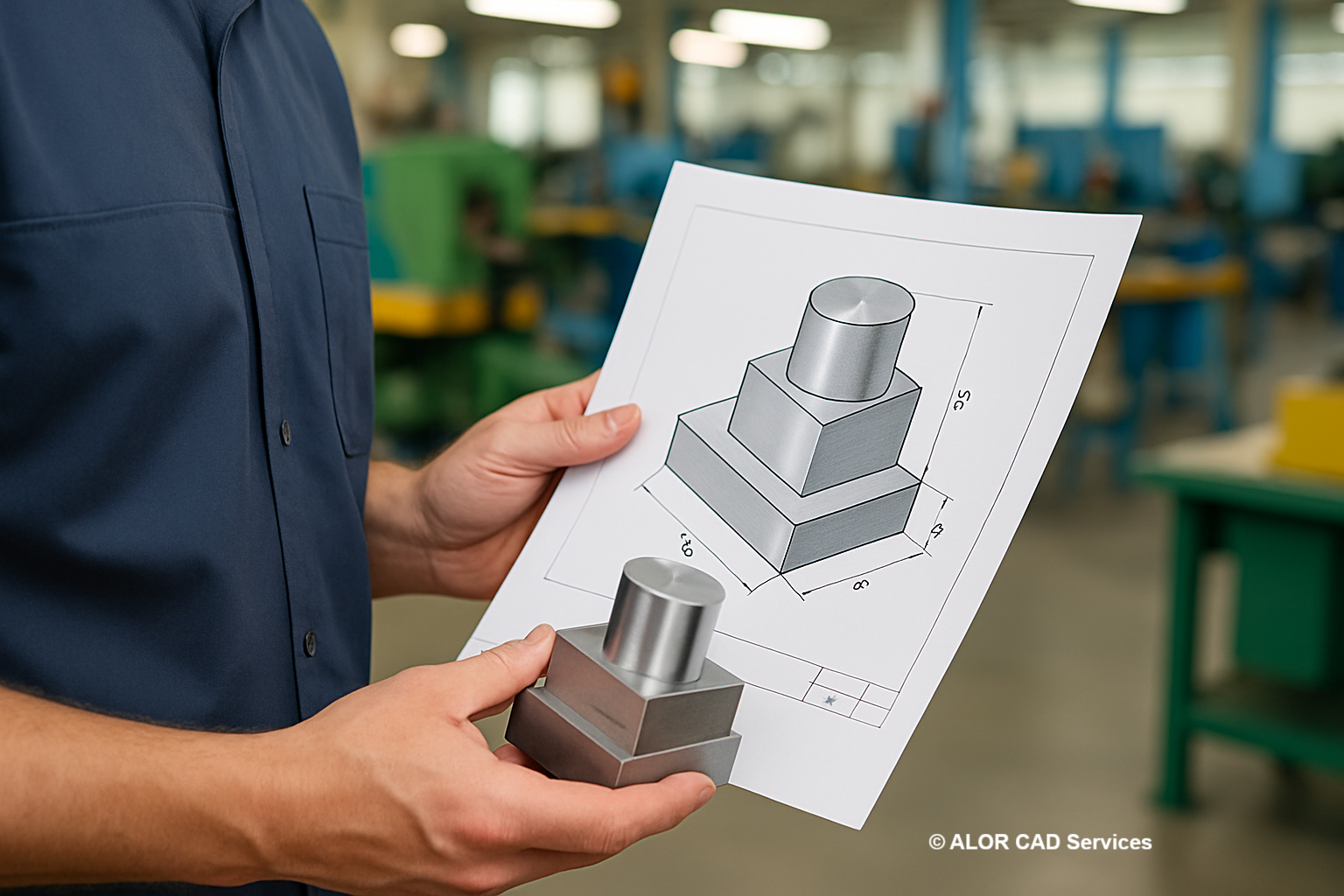

08 Sep How Professional 3D CAD Modeling Enhances Product Accuracy & Manufacturability

In today’s fast-paced engineering environment, product development requires both precision and efficiency. Engineers and R&D teams are under pressure to design products that not only meet performance expectations but are also optimized for manufacturing. Traditional design processes often left gaps between concept and production, which resulted in costly revisions. Professional 3D CAD modeling services now provide the bridge between design intent and manufacturing readiness. By focusing on accuracy and manufacturability, CAD has become an essential tool for industries that rely on engineering innovation.

What are 3D CAD Modeling Services?

3D CAD modeling services involve the creation of digital representations of products, parts, or systems. CAD, which stands for Computer-Aided Design, enables engineers to create detailed models that represent both the geometry and functional behavior of a product. Unlike simple 2D drawings, 3D models provide a complete visualization of the product, including internal structures, material tolerances, and assembly considerations.

Industries such as aerospace, automotive, consumer electronics, industrial machinery, and healthcare all rely heavily on 3D CAD modeling. These services make it possible to create complex components with high precision, simulate real-world conditions, and test designs before committing to fabrication.

The Role of Accuracy in Product Design

Accuracy is one of the most critical elements in product design. A small error in a dimension or tolerance can multiply into significant problems once the product reaches the manufacturing floor. Tolerance modeling ensures that every component is measured and aligned correctly so that parts fit and function as intended.

Without proper tolerance modeling, engineers risk introducing misalignments that lead to higher production costs, material waste, and delayed timelines. Accurate CAD models eliminate these risks by providing exact specifications that can be directly transferred to fabrication equipment. This level of precision reduces rework and ensures that the final product performs exactly as designed.

From Design to Manufacturing: Bridging the Gap

One of the biggest challenges in engineering has always been the gap between conceptual design and real-world manufacturing. Professional 3D CAD modeling services solve this challenge by producing fabrication-ready models. These models include details like geometric tolerances, assembly instructions, and material specifications, ensuring that manufacturers have everything they need to begin production with confidence.

Parametric design is another key advantage of CAD modeling. With parametric design, engineers can quickly make changes to dimensions or features while maintaining consistent relationships between different parts of the model. This flexibility speeds up the design-to-manufacturing process and allows teams to respond quickly to design feedback.

By using CAD to validate designs early, companies can detect potential flaws before production begins. This reduces the risk of costly tooling changes and prevents errors that might otherwise appear late in the development cycle.

Enhancing Manufacturability with Engineering CAD

Engineering CAD does more than create accurate models. It enhances manufacturability by providing tools for simulation and prototyping. Engineers can run virtual tests on models to understand how a product will behave under stress, heat, or motion. These insights allow teams to make informed design decisions without the expense of physical prototypes.

Another major advantage is the ability to foster collaboration between R&D and manufacturing teams. With a shared CAD model, both teams can work on the same data, exchange feedback in real time, and ensure that designs are optimized for production. This integrated approach reduces the number of design iterations and accelerates the product development timeline.

The result is a streamlined process where design accuracy directly supports manufacturability, leading to faster market entry and reduced production costs.

Future of CAD in Engineering and R&D

The future of CAD is being shaped by advances in automation and artificial intelligence. CAD systems are increasingly incorporating AI-powered features that can suggest design improvements, automatically adjust tolerances, and even generate optimized models based on performance requirements. Digital twins are also gaining prominence, allowing engineers to create a virtual replica of a product that can be tested and monitored throughout its lifecycle.

For R&D teams, these developments mean shorter design cycles and more innovative solutions. As CAD technology continues to evolve, its role in enhancing both accuracy and manufacturability will only become more vital.

Why Choose ALOR CAD Services

ALOR CAD Services specializes in delivering professional 3D CAD modeling services that are tailored to the needs of engineers and R&D teams. With extensive experience across multiple industries, ALOR CAD Services understands the importance of precision, manufacturability, and real-world application.

The team focuses on creating fabrication-ready models that eliminate design flaws and accelerate production. Whether it is tolerance modeling, parametric design, or detailed engineering CAD, ALOR CAD Services ensures that every project is handled with accuracy and efficiency. By partnering with ALOR CAD Services, companies gain a reliable extension of their in-house engineering team, capable of handling projects of any complexity.

You are in safe hands!

Professional 3D CAD modeling services play an essential role in bridging the gap between product design and manufacturing. By emphasizing accuracy, tolerance modeling, and fabrication-ready models, CAD empowers engineers and R&D teams to innovate with confidence. The ability to create precise, manufacturable designs not only reduces errors but also accelerates the path to market.

For organizations seeking to improve their product development process, partnering with an experienced provider like ALOR CAD Services can make all the difference. With expertise in engineering CAD and a focus on real-world applications, ALOR CAD Services helps companies achieve the highest standards of accuracy and manufacturability.

If your team is ready to bring precision and efficiency to your next project, explore the professional 3D CAD modeling services offered by ALOR CAD Services and take the first step toward design excellence.

Frequently Asked Questions (FAQ)

1. What are the benefits of outsourcing 3D CAD modeling services?

Outsourcing provides access to specialized expertise, advanced tools, and faster turnaround times. It also reduces overhead costs for companies that may not have dedicated CAD resources in-house.

2. How does tolerance modeling improve manufacturability?

Tolerance modeling ensures that parts fit and function as intended during assembly. This reduces errors, eliminates misalignment, and minimizes the need for costly adjustments during production.

3. Can CAD models be used directly for fabrication?

Yes. Fabrication-ready CAD models include detailed specifications that can be transferred to CNC machines, 3D printers, or other manufacturing equipment, ensuring accuracy from design to production.

4. What industries benefit most from 3D CAD modeling?

Industries such as aerospace, automotive, electronics, industrial equipment, and healthcare use CAD extensively due to their need for precision and complex product design.

5. How does parametric design help R&D teams?

Parametric design allows R&D teams to quickly adjust product dimensions or features without reworking the entire model. This flexibility saves time and improves adaptability during the development process.