20 Aug How Unified Mechanical and Electrical CAD Teams Streamline Product Development

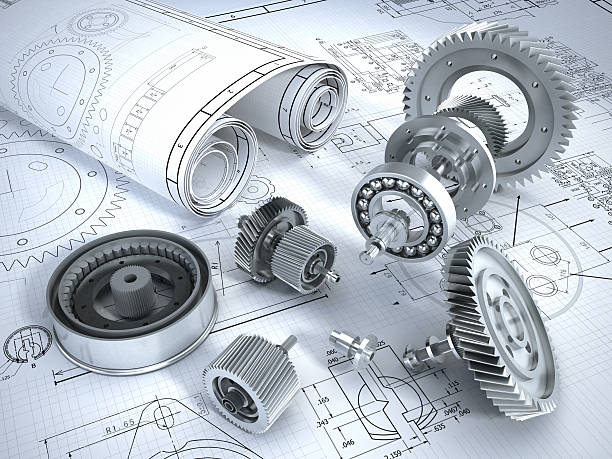

For decades, mechanical and electrical engineering teams have worked in parallel but disconnected workflows. This siloed approach often leads to communication gaps, integration errors, and delays in the product development cycle. As modern products become more integrated—think smart home devices, electric vehicles, and industrial automation the need for a unified approach has never been greater.

Unified CAD services address this need by combining both disciplines into one collaborative environment. This blog explores how OEMs and product teams can leverage unified mechanical and electrical CAD workflows to build better products faster, with fewer errors and greater innovation.

What Are Unified CAD Services?

Unified CAD services refer to an integrated approach to product design where mechanical and electrical engineering teams work collaboratively using shared digital tools and data. Rather than working in isolation and syncing up later in the process, both teams contribute to a common digital model from the beginning.

This unified method supports real-time collaboration, faster iterations, and early conflict detection. It eliminates the back-and-forth handoffs that traditionally delay product development, replacing them with synchronized workflows that reduce errors and support full-cycle CAD delivery from concept through to manufacturing.

Why Electromechanical Design Demands Integration

Today’s products are rarely purely mechanical or purely electrical. Whether it’s a medical device with embedded sensors or a drone with motor control systems, most products combine hardware and electronics into tightly integrated electromechanical systems.

When CAD design teams work separately, mechanical housings may not accommodate PCBs, or wire routing may interfere with moving parts. These integration issues, discovered late in the process, force expensive redesigns and testing cycles.

Unified CAD services allow these challenges to be addressed earlier. Both mechanical and electrical components are designed with full visibility of the entire system, enabling teams to resolve spatial, thermal, and functional conflicts before they become manufacturing issues.

Collaborative CAD: Creating Shared Digital Workspaces

Collaborative CAD is a foundational feature of unified CAD services. It allows multiple engineers—across domains and locations to work on the same model in real time. These digital workspaces are not just file-sharing platforms; they enable truly interactive, coordinated design efforts.

When an electrical engineer adjusts a wire harness, the mechanical team can immediately see how it affects enclosure design. Similarly, changes to mounting brackets or component placements by the mechanical team can trigger real-time updates to the electrical layout.

This level of transparency improves communication, speeds up decision-making, and ensures that all changes are evaluated within the full context of the product. Collaborative CAD is especially valuable for agile teams working with rapid iteration cycles, where delays and misalignment are costly.

The Importance of Integration Tools in Unified CAD

For unified CAD services to function effectively, robust integration tools are essential. These tools connect different software environments such as mechanical CAD, electrical CAD, simulation engines, and documentation systems—so that data flows automatically and accurately between them.

For example, integration between SolidWorks Mechanical and SolidWorks Electrical ensures that electrical routing, panel layouts, and harness designs are aligned with mechanical constraints. When a mechanical change is made, it immediately updates the electrical context, and vice versa.

Beyond software compatibility, integration tools also handle repetitive tasks such as validating design rules, generating bills of materials, and preparing files for simulation or production. This level of automation reduces human error and frees engineers to focus on high-value creative tasks.

Full-Cycle CAD Delivery: From Idea to Production

Unified CAD services offer more than just design tools they enable a full-cycle delivery model that spans concept development, simulation, prototyping, and manufacturing. This continuity is vital for modern product teams that must adapt quickly to feedback, market shifts, or design updates.

Concept Development

When teams collaborate from the start, feasibility assessments are more accurate. Mechanical and electrical engineers contribute ideas based on their unique constraints, resulting in stronger, more realistic initial designs. With AI-powered tools, early-phase designs can also benefit from component suggestions and layout optimization.

Design and Simulation

As the design matures, integrated simulation tools help validate functionality across both mechanical and electrical domains. Designers can evaluate structural strength, thermal performance, and electrical safety all within the same workflow. Problems are identified and resolved long before a physical prototype is created.

Prototyping and Testing

Once the design passes simulation, teams can quickly produce 3D-printed models or digital twins that incorporate both mechanical and electrical components. These unified prototypes help teams test functionality in real-world conditions without the need for separate validation processes.

Manufacturing and Handoff

Unified CAD ensures that final production files are complete, accurate, and consistent. Bills of materials, wiring diagrams, and assembly drawings are automatically generated based on the latest model. This reduces the risk of costly errors or delays on the factory floor.

The Role of AI in Streamlining Unified CAD Workflows

Artificial Intelligence is transforming how design teams use CAD systems. In the context of unified workflows, AI enhances efficiency, accuracy, and decision-making by providing intelligent design suggestions and automation.

For example, AI can detect potential interference between components, suggest alternative part placements, or recommend routing paths based on past design patterns. It can also automate routine tasks such as rule-checking, documentation formatting, and generating multiple design configurations.

AI’s ability to learn from previous projects adds another layer of value. By analyzing what worked well in past designs, AI can guide teams toward best practices, reducing trial and error and accelerating innovation. When combined with collaborative and integrated CAD environments, AI ensures that every design decision is faster and better informed.

Improving Workflow Efficiency Through Unified Design

The biggest advantage of unified CAD services is the overall boost to workflow efficiency. When design teams operate on shared platforms with real-time updates, fewer mistakes occur. There are fewer handoffs, fewer duplicated efforts, and fewer delays due to incompatible files or late-stage changes.

This unified approach leads to shorter development cycles, faster prototyping, and smoother transitions into manufacturing. It also creates a more agile environment where changes can be implemented without disrupting the entire process. In industries where time-to-market is critical, this agility offers a clear competitive advantage.

Choosing a Unified CAD Services Partner

Implementing unified CAD in-house can be resource-intensive, especially for companies without the infrastructure or cross-domain expertise. This is where an experienced CAD services partner can make a difference.

A strong partner will bring deep knowledge of both mechanical and electrical CAD, understand integration tools and PDM systems, and have a proven track record in delivering full-cycle CAD support. They should also be capable of scaling services to meet your specific needs, whether that’s rapid prototyping, compliance documentation, or manufacturing-ready models.

ALOR CAD, for instance, offers unified design solutions tailored to OEMs and product teams. Their expertise spans across disciplines, ensuring smooth collaboration, AI-powered design insights, and efficient delivery pipelines.

Conclusion: A Smarter Way to Develop Products

Unified CAD services offer a powerful solution to the growing complexity of modern product development. By aligning mechanical and electrical design within a shared digital environment, teams can work faster, reduce integration errors, and deliver more innovative products to market.

Whether you’re building advanced robotics, consumer electronics, or industrial machinery, the need for seamless collaboration is only going to grow. Unified CAD workflows backed by AI, integration tools, and effective data management are no longer optional they’re essential to staying competitive.

Now is the time for OEMs and product development teams to embrace this approach and build a more efficient, agile, and collaborative future.

Email: info@acscadservices.com

Call: 508.978.4628

Contact us today!

FAQs

What are unified CAD services?

A: Unified CAD services refer to integrated workflows where mechanical and electrical design teams collaborate in a shared environment using synchronized tools, data, and platforms.

Why is electromechanical design more important now?

A: Modern products often combine both mechanical and electronic components. A unified approach ensures these elements are designed together, reducing conflict and accelerating development.

What does collaborative CAD mean in this context?

A: Collaborative CAD allows engineers from different domains to work on the same model in real time, improving communication and minimizing design errors.

How do PDM systems support unified workflows?

A: PDM systems centralize design data, track revisions, manage user access, and help teams stay aligned throughout the product lifecycle.

How does AI improve unified CAD workflows?

A: AI enhances CAD workflows by suggesting design improvements, detecting issues early, automating routine tasks, and learning from past projects to guide future designs.